Key Takeaways

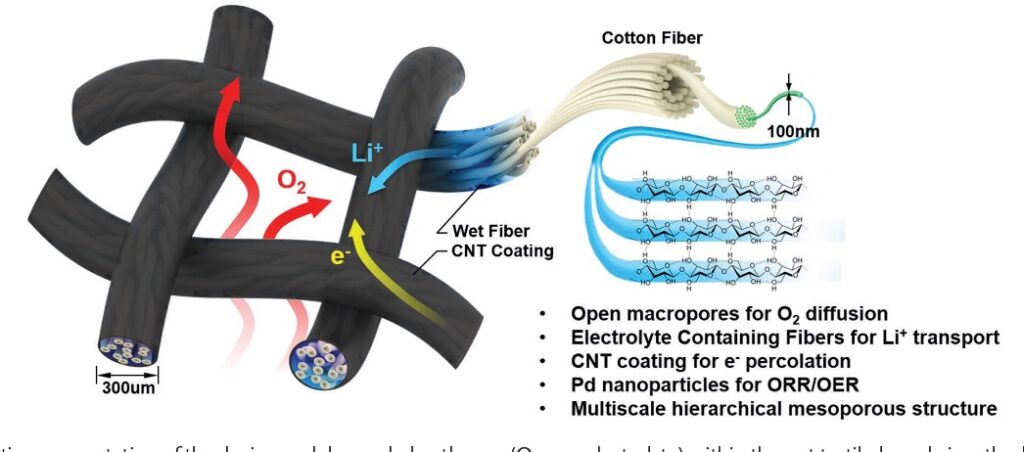

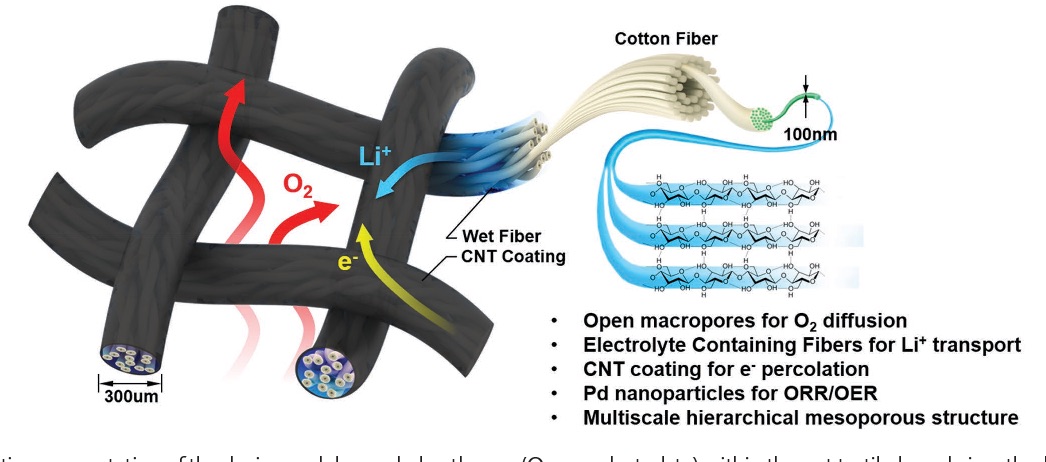

- Developed a textile-based air cathode for lithium-air (Li-O2) batteries.

- Unique structure allows for separate pathways for oxygen gas and electrolyte, improving battery performance.

- Delivers high discharge capacity, low overpotential, and stable operation.

- Applicable to other multi-phase reactions, such as fuel cells and water splitting.

- Potential for flexible and wearable battery applications.

Introduction:

Lithium-air (Li-O2) batteries have captured the attention of researchers due to their potential for delivering high energy density, making them promising candidates for next-generation energy storage systems. However, challenges related to oxygen and electrolyte management have hindered their practical implementation.

Textile-Based Cathode: A Revolutionary Approach:

A groundbreaking study published in [insert journal name] presents a novel approach to Li-O2 battery design using a textile-based cathode. This unique cathode structure addresses the limitations of conventional designs by introducing separate pathways for oxygen gas and electrolyte.

Key Features and Advantages:

- Decoupled Pathways: The textile material’s woven mesh allows oxygen to flow freely, while the electrolyte moves along the textile fibers. This separation enhances the battery’s performance by promoting efficient oxygen transport and electrolyte utilization.

- High Discharge Capacity: The textile-based cathode exhibits an impressive discharge capacity, indicating its ability to store a significant amount of energy.

- Low Overpotential: The battery operates with a low overpotential, which minimizes energy losses during charging and discharging, resulting in improved efficiency.

- Stable Operation: The textile cathode demonstrates stable operation over multiple cycles, indicating its long-term reliability and durability.

Potential Applications Beyond Li-O2 Batteries:

The unique design of the textile-based cathode opens up possibilities for its application in various electrochemical systems, including:

- Fuel cells

- Water splitting

- Redox flow batteries

These applications involve multi-phase reactions, and the textile cathode’s ability to manage gas and electrolyte flow could prove advantageous.

Wearable and Flexible Devices:

The flexibility of the textile material suggests the potential for integrating the textile-based cathode into flexible and wearable energy storage devices. This could pave the way for the development of next-generation wearable electronics and medical devices.

source: https://onlinelibrary.wiley.com/doi/10.1002/adma.201704907